Ⅰ.Us histoarje

BEIJING DEMINA PRECISION MACHINERY CO., LTD waard oprjochte yn 2003. As de advokaat en pionier fan 'e yndustry, Deming, hat it bedriuw ryk sammele. ûnderfining yn technology en tsjinst foar produktferkeap, wijd oan it jaan fan brûkers in mear wiidweidige oplossing. Op it stuit, ús bedriuw ûntwikkele lannen allerhanne cutting ark en drill slypjen apparatuer, kin leverje de meast geskikte produkten foar ferskillende brûkers, en soargje foar in folslein oanbod fan technyske advys tsjinsten; yn Peking it ark service sintrum, Tianjin en omlizzende gebieten jouwe manufacturing de totale carbide ark, de totale alloy bit en net standert cutting ark en grinding; hat ek mear as 10 jier fan masine ark manufacturing en ûntwikkeling ûnderfining fan ús bedriuw, ûntwikkeling en produksje fan BT150 rige diamant ark grinding masine, universele ark grinding masine en BT560 type ark detection ynstrumint, tool grinding masine CNC transformaasje en ark grinding applikaasje software. Yn 2016 hawwe wy in folsleine produksje- en produksjebasis foar masjine-ark fêstige yn Jing'an County, Jiangxi Province, en fêstige Jiangxi Geqi Grinding Technology Co., Ltd. en Jiangxi Demina Precision Machinery Co., Ltd. de training fan snijtalinten.

Ⅱ.Our Fabriek

Us fabryk hat in totale ynvestearring fan 122,8 miljoen yuan, beslacht in gebiet fan hast 50 acres, wêrfan it bougebiet 23.466 kante meter is, mei 1 kantoargebou, 2 pakhuzen en 4.000 kante meter oan wittenskiplik ûndersyk en wenkompleks.

As in yndustry lieder yn 'e ûntwikkeling en fabrikaazje fan ark grinding masines, Demina Manufacture Center hat tsientallen jierren fan oerfloedich ûnderfining yn it ûntwerpen fermogen en profesjonele manufacturing arsjitektuer. It sintrum is net allinich in liedende leveransier fan PCD-ark-slypmasines en tool-analyzers, mar leveret ek tsjinsten lykas CNC-transformaasje fan hânbestjoerde arkslypmasines, it reparearjen fan CNC-arkslypmasines, it opwurdearjen fan kontrôlesysteem, it bywurkjen fan software en sa fierder.

Ⅲ.Our Products

4-Axis CNC PCD Tool Grinder BT-150D

< 32>

De masine is geskikt foar massive produksje fan carbid ynfoegje, PCD en CBN ynfoegje. Sadree't it sintrum is klear, sil grinding automatysk dien wurde. It sels konsumpsje fan grinding tsjil kin wurde mjitten en kompensearre troch it systeem, sadat produksje mei lange syklus tiid kin wurde mjitten.

| De diameter fan it grindwiel | 150mm |

| Direct Drive Spindle mei wetterkoeling | 3KW |

| RPM fan slijpspil | 0~3.000RPM |

| Feroarbere klaringshoek | -5° ~25 ° |

| Maksimale fergrutting fan optyske mikrokop | 4 kear |

| Yndustriële PC en display | 15 " |

| Fergrutting fan CCD-measuringsysteem | 100kear |

| Koelvloeistoftank mei filterpapier | oer 70L |

| Elektryske oanbod | 12Kw |

| Spanning oanfrege | 380V/Three phrace/50Hz |

104>Gewicht mei koelmiddeltank106>2000Kg108>109>110>111>112>BT-150J Superhard Tool Grinding Machine114 >

BT-150J PCD Tool Grinder is betrouber yn prestaasjes en maklik te betsjinjen. It freget heul bytsje hânfeardigens. It swingen fan grinding tsjil regele troch PLC is glêd en sûnder omkearde trilling. Sûnder tsjilhandgrepen is it maklik om it swingberik, frekwinsje en swingposysje te kontrolearjen troch op de knop te drukken. De masine dy't 'rapid feed' en 'precision feed' brûkt om rappe feed / retraction (0.5mm / turn) en wurkfeed (3mm / turn) te foltôgjen. Dit soarget foar de produksje effisjinsje en feeds presyzje.

| Main Technical Parameters: |

| 1 | De diameter fan it slijpwiel | 150mm |

| 2 | Direct Drive Spindle with Water Cooling | 3KW<143 > |

| 3 | RPM fan grindspil | 0~3000RPM |

| 4 | PLC Numerike kontrolearre oscillaasje en kontrôle op it paniel |

| 5 | Max. Oscillaasjeberik | 30mm |

| 6 | Max. Oscillaasjefrekwinsje | 60 kear/minút |

| 7 | Snelle oanpak weromlûke en presys feeding | 3mm/beurt <182 > 0,5 mm/beurt |

| 8 | Feedresolúsje | 0,001 mm |

< 196>9198>Fergrutting fan CCD-measuringsysteem| 100 kear | 202>203>204>10206>15 Industrial Displayer15 |

| 11 | Elektryske oanfier | 12Kw |

| 12 | Spanning oanfrege | 380V/Three phrase/50Hz |

| 13 | Kompresje fan luchtremming op rotaasjeas | 6bar | <234 >

Boarslijpmasine BT-40

Boar, tap, fersinker en stapboarkan wurde grûn op BT-40 sûnder wiidweidige training. De fertikale slijpwiel makket web thinning hiel maklik. Seis-kaak chuck mei hege krektens garandearret de run-out in drill fertsjinnet.

Slijpdiameter | 2~40mm |

| Punthoek | 40°~180° |

<268 >Horizontale wielspilkracht| 0.76KW |

| Vertikale wielspilkracht | 0.18KW |

| Tsjil snelheid | 3380 rpm |

| spanning | 24V |

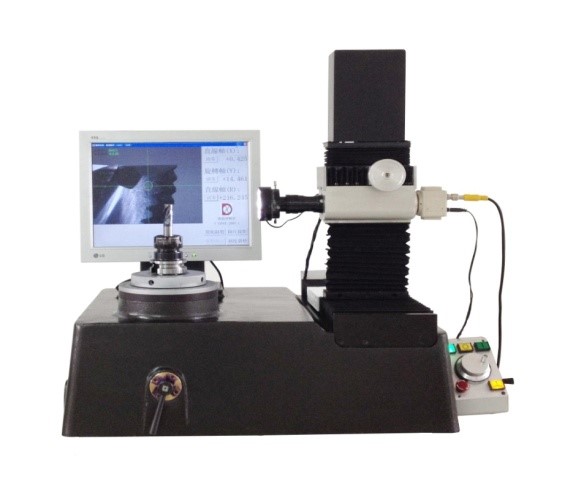

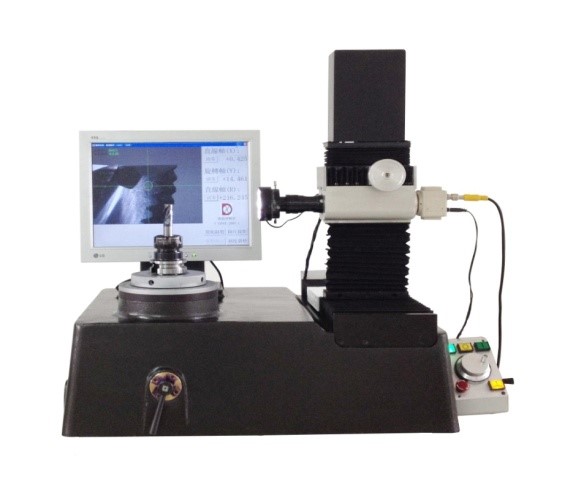

BT-560 Tool Analyzer

De analysator wurdt brûkt foar it mjitten fan de geometryske eleminten (lykas de diameter, radius, en de snijhoeke) fan boren en cutters . It makket gebrûk fan 'e arkmikroskoop en CCD-kamera om it byld te fergrutsjen en de real-time werjefte te realisearjen, en de bestjoeringshendel en elektroanyske hânwiel om de mjitposysje fluch en krekt yn te stellen.

BT-150E 5-Axis CNC Tool Grinding Machine

BT-150E 5-Axis CNC Tool Grinder is foarsjoen fan in spesjaal CNC systeem, mei tool grinding applikaasje software basearre op Windows XP. It kin grind boren, ein molens, en bal noas fan HSS en carbid. Alle programma's kinne wurde bewarre, kopiearre, omneamd en wizige. Foardat jo begjinne mei it slypjen fan it ark, kin 2D-simulaasje makke en befêstige wurde, sadat goede oanpassing mooglik is.

| Technyske gegevens: Work Head Frame | Hydraulic chuck BT 40 |

| Tool Diameter Range | 3-25mm |

< 333>Maksimum fan arklengte | 200mm | | Maksimum fan arkdiameter | 125mm |

<346 >Riel middengat| 20mm |

| Aantal tsjil | 1-3 |

| Spindle Power< 359> | 5KW |

| Max.of Wheel Speed | 6000rpm |

| X-Axis Longitudinale Traverse | 360mm |

| Z-as fertikale traverse | 180mm |

| Y-as horizontale traverse | <384 >190mm

| A-as Traverse | Endless |

| W-Axis Traverse | 0~200 ° |

| De krektens fan lineêre as | 0.001 mm |

| De krektens fan de rotearjende as | 0.001° |

| Maksimum lineêre as feedrate | 15m/min |

| Maksimum fan rotaasjeas | <420 >60rpm

| Controlling System | 5-assige kontrôlesysteem fan Dútslân Beckhoff |

| Measuring System | Data Encoder |

| Dimensje | 2300x1800x2400(h)mm |

| Gewicht | 2000kg | < 446>

| Main Power | 380V |

| Machtspanning | 10kw |

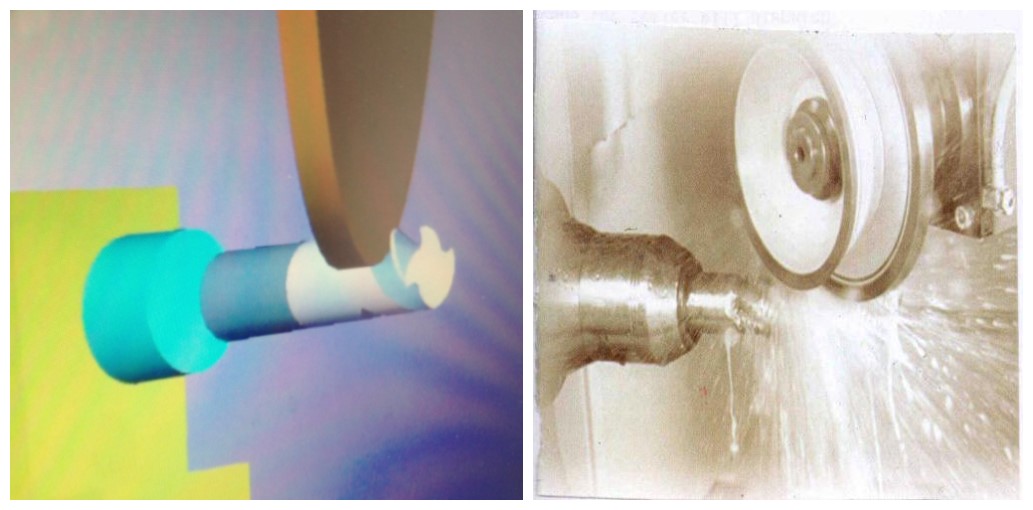

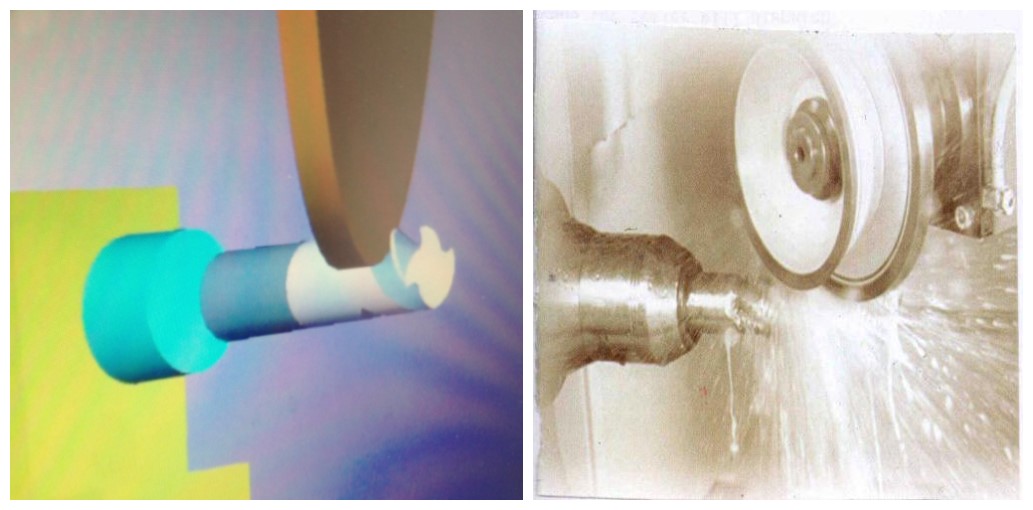

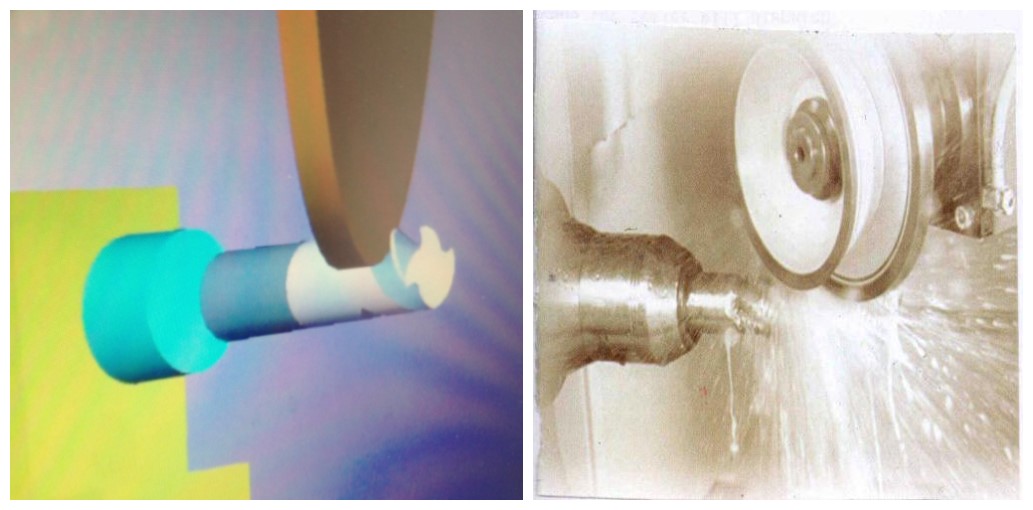

<460 >Ⅳ.Product Application

De produksje fan BT150-searje diamant-ark-slijpmasjine is geskikt foar massive produksje fan karbid-ynserts, PCD- en CBN-ynserts.

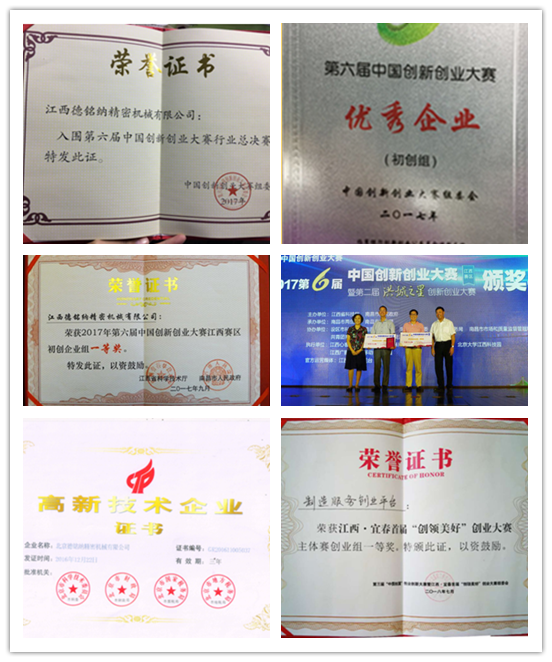

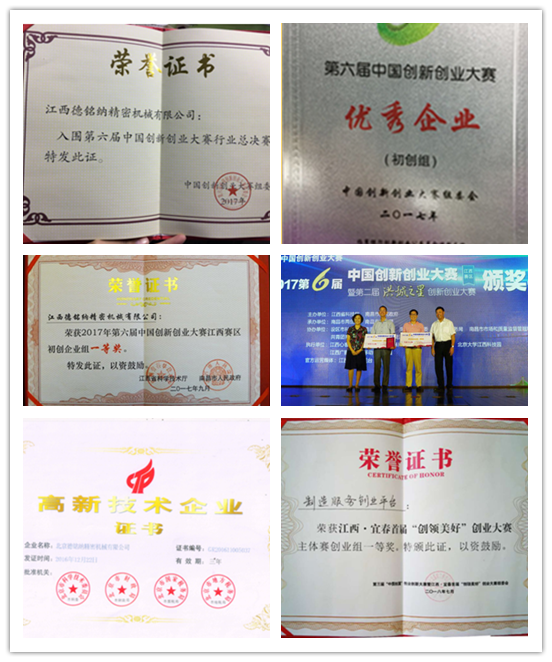

Ⅴ.Our Certificate

1. 150B 2-axis CNC diamant ark grinding masine wûn it Beijing Nije Technology en Nij Produkt Sertifikaat

2. 150D 3-as CNC diamant ark grinding masine wûn de Beijing Nije Technology en New Product Certificate

3. Beijing Demina Precision Machinery Co., Ltd. krige it hege-tech ûndernimmingssertifikaat

4. Beijing Demina Precision Machinery Co., Ltd. krige Zhongguancun High-tech Enterprise Certificate

5. Earste priis fan 'e 6e China Innovation and Entrepreneurship Competition yn Jiangxi Province

6. De Excellence Award yn 'e Advanced Manufacturing Industry fan' e 6e China Innovation and Entrepreneurship Competition yn 2017

7. Yn 2018, de earste priis fan 'e ûndernimmende groep fan' e earste "Creation of the Beautiful" Entrepreneurship Competition yn Yichun, Jiangxi

8. Mr.Shu Zhiyong -de algemien direkteur fan Demina Precision waard selektearre as in liedend ûndernimmend talint yn it "Dûbeltûzenplan" fan 2018 yn 'e provinsje Jiangxi.

Guon sertifikaatfoto's binne as folget:

Ⅵ.Produksjemerk

Us produkten binne basearre op 'e Sineeske merk. En ús klanten omfetsje mear as 20 provinsjes, gemeenten en autonome regio's yn Sina, en wurde eksportearre nei de Feriene Steaten, Meksiko, Turkije en Japan, Súd-Korea, Maleizje, Tailân, Yndia, Singapore, Súdeast-Aazje en oare lannen.<487 >

Ⅶ.Our Service

Foarferkeap:

Proaktyf leverje de relevante ynformaasje fan ús produkten oan klanten, jouwe guon suggestjes oan klanten om de masine te keapjen dat it bêste past by har behoeften, en behearsket de metoaden fan gebrûk en ûnderhâld fan 'e masine.

On-sale Service:

Respektearje klanten en leverje de bêste tsjinst.<501 > Soargje foar produkt technyske oerlis foar brûkers; befêstigje wat se nedich binne en jouwe folsleine oplossingen foar brûkers.

Nei-ferkeap:

<513 >

Wy sille de spoaren folgje fan it heule proses fan produkttsjinst en kwaliteit, folsleine oandacht besteegje oan klachten en suggestjes fan klanten, merkynformaasje prompt feedback meitsje, yntiidske oanpassingen meitsje en produkten direkt weromjaan dy't feroarsaakje kwaliteitsproblemen foar ús, sadat de produktkwaliteit fan it bedriuw en it servicenivo konstant ferbetterje en de mearderheid fan brûkers better tsjinje.

Hot Products

-

-

-

BT-150M Tool Grinder

BT-150M Tool Grinder

Featured produkt:

Demina Precision Machinery Co., Ltd, a professional BT-150M tool grinder manufacturer, and BT-150M tool grinder supplier, we produce China BT-150M tool grinder is designed for the economical manufacturing and regrinding of cutting tools made from PCD, PCBN, CVD, tungsten, carbide, and other materials. It can grind angles and radii on standard and special turning and milling inserts, boring tools, grooving tools and many types of special turning tools. The equipment is manufactured by a professional BT-150M tool grinder manufacturer, among them, the Semi-auto tool sharpening machine is very popular and used by users.

-

PCBN Insert And PCD Insert Products

PCBN Insert And PCD Insert Products

Featured produkt:

1.PCBN insert and PCD Insert Products introduction:

PCBN is short for polycrystalline cubic boron nitride. PCBN Insert has high hardness, microhardness HV700~9800Mpa, similar to diamond hardness, high thermal conductivity, and can withstand high cutting temperature. Hardened steel has high strength, high hardness, low plasticity, large cutting force, high cutting temperature, and high requirements for tool resistance, wear resistance, and thermal conductivity. According to the current processing technology, PCBN Insert is very suitable for processing hardened steel tools. It can process high hardness cast iron, steel, gray cast iron, stainless steel, and so on.

PCD is short for polycrystalline diamond, which is translated into Chinese as polycrystalline diamond. Polycrystalline diamond refers to a polycrystal sintered at a high temperature (1400℃) under high pressure by mixing diamond micro powder (micron size) with a small amount of metal powder (such as Co, etc.).Industrial use is mainly PCD composite, PCD insert is to use PCD composite blade as raw material. PCD insert has the advantages of high hardness, low friction coefficient, low thermal expansion coefficient, wear resistance, long life, and so on.

In recent years, as long as the tool to car generation of grinding, milling generation of grinding processing, PCBN insert and PCD insert products are very popular.

-

APE-40 UP-Drill And Tap Resharpening Machine

APE-40 UP-Drill And Tap Resharpening Machine

Featured produkt:

High-quality APE-40 UP-drill and tap resharpening machine using simple machine fixtures, Cuoghi sharpening machines sharpen twist drills with 40° to 180° tip angles, multi-step drills, pilot bits, diamond drills, prismatic and self-centering drills, flat bits, center drills, countersinks, expanders and taps with 1 to 12 right and left cutting edges, as illustrated in a few examples. APE-40 UP-drill and tap resharpening machine can grind drills. Demina Precision Machinery Co., Ltd, is an APE-40 UP- sharpening machine for sale and Semi-auto tap grinder wholesale, welcome to come to consult.

-

Hot Nijs

-

12

2023.05

PCD metal cutting tools can use PCD materials with high hardness, high wear resistance, high thermal conductivity, and low friction coefficient to achieve high precision, high efficiency, high stability, and high surface finish of non-ferrous metals and wear-resistant non-metallic materials. This kind of tool from the structure can be divided into welding PCD tool and indexable PCD blade.In recent years, PCD tools with standard shank have developed rapidly, such as PCD milling cutter with shank, PCD boring cutter, PCD reamer, etc. The tool shank types are mainly cylindrical shank, taper shank, and HSK shank. This kind of tool (especially the multi-tooth tool) is characterized by the cutting edge of the shank runout small (such as the blade length of 30mm HSK handle PCD milling cutter cutting edge runout is only 0.002mm), especially suitable for a variety of non-ferrous metal parts of the forming surface, hole, step hole and other large quantities of high-speed processing. For example, the PCD high-speed milling cutter with aluminum matrix cutter head (six edges, diameter 100mm), the maximum speed can reach 20,000R/MIN, above, the cutting speed can reach 7,000M/MIN, suitable for forming surface processing of automotive parts.The indexable PCD blade is made by inlaying a PCD knife blank on the indexable carbide blade and then grinding it. It can be clamped on the cutter bar, cutter holder, or cutter head of various CNC machine tools and used for high-reliability mass processing. With the increasing popularity of CNC machine tools, machining centers, and automatic production lines, the use of indexable PCD blades is more and more, and the tool’s durability can be improved dozens of times compared with carbide tools.(2) PCD woodworking toolsPCD woodworking tools can be divided into PCD saw blades and PCD shaped woodworking milling cutter two categories.PCD saw blade is to weld the PCD blade blank on the saw blade matrix and then warpThe structure of the PCD saw blade is similar to that of the carbide saw blade after grinding. The difference is that the front Angle of the PCD saw blade is smaller than that of the carbide saw blade, generally, 5° ~ 10°, wedge Angle 65° ~ 75°, the size of the saw blade is generally from 100 to 450mm, and the number of sawteeth can be up to 72 teeth.The main varieties of PCD forming woodworking milling cutter are used for processing Al2O3 layer of laminated wood floor trimming knife, PCD groove knife, PCD furniture forming knife, etc. Its processing method is the shape of PCD cutting tool one-time copy (or combination) to be processed wood. The cutting speed of PCD forming woodworking milling cutter can reach 3,000m/min, and the cutting volume can reach several meters per minute. The cutter’s durability is dozens or even hundreds of times that of carbide cutting tools. Because of its high efficiency and high durability, it is especially suitable for mass processing.

Lês mear

-

12

2023.05

PCBN metal cutting tools can also be divided into welding PCBN tools and indexable PCBN blade two categories.Welding type PCBN tool is the PCBN insert blank welded on the steel matrix by grinding, mainly turning tool, boring tool, reamer, and so on. PCBN tools are mostly used for wear-resistant ferrous metal processing, so the tool Angle can not be too small, the tool rectangle is generally -5° ~ 5°, the back Angle is generally 3° ~ 10°, intermittent cutting is generally negative chamfering.PCBN insert of transposition structure (mainly for the lathe tool and milling tool) is generally in a corner of the transposition cemented carbide blade inset welding a PCBN insert blank, by grinding. In consideration of the more expensive and regrinding knife blank and other reasons, generally only made of a knife tip. With the improvement of welding process quality, the shear strength can reach 0.78kg/m². With the PCBN insert blank size smaller and smaller, not regrinding PCBN blade price also decreases. Because PCBN tools have high wear resistance and long life, it is also ground for many times, many customers like to choose PCBN metal cutting tools for product processing.It needs a tool grinding machine for grinding PCBN inserts. Beijing Demina PCBN tool grinding machine can grind and regrind PCBN cutting tools with high efficiency.

Lês mear

-

12

2023.05

Grinding Procedures Of BT-150N Tool GrinderAt first, set the grinding wheel inclination as the second clearance angle (normally from 0°to 18°), and turn the rotary table at a proper position so that the left cutting edge parallel to the X-axis of the hairline on the video displayer. That is the cutting edge parallel to the grinding wheel end face. Turn the fast feed handwheel to move the tool immediately in front of the grinding wheel end face, and then feed forward with figures screwing the micro feed wheel. The grinding wheel is removing the PCD&CBN material until you stop. Try it one or more times until the new cutting edge appears. Do the same to the second cutting edge.Secondly, center the tooltips again by turning the two handwheels on the cross worktable. Drive the grinding wheel quickly forward until the PCD&CBN tool is near to the grinding wheel, and then feed ahead while swinging the rotary table. Radius cutting tip is forming gradually. As soon as the radius cutting edge coincides with the two linear cutting edges stop the feeding. Finally, set the grinding wheel inclination as the first clearance angle (normally from 5 ° to 8 ° ), do the same to the tools so that a very narrow flat (roughly 0.02mm thickness) comes into being on the cutting edge. The way described above is a normal method, and a special and more reasonable method is highly encouraged and reported to Demina precision. Special fixture design and even emendation to the machine will be considered by Demina as innovation.

Lês mear

-

12

2023.05

Hoog Kwaliteit Comfortabele en Antislip Gel Auto Stoel Kantoor Stoel Mat Pad Koeling Kussen Rolstoel Schuim Ijs Gel ZitkussenHoegekwaliteitscomfortabele en antislipgel autostoelkantoor stoelmat pad koelkussen rolstoel foam ice gel zitkussen.Hochtswertig, komfortabel aanti-slip Gel Autositz Bürostuhl Matte Pad Kühlkissen Rollstuhl Schaumstoff Ice Gel Sitzkissen.Hoogkwalitatief, comfortabel en antislip Gel autostoel, kantoorstoel, mat, kussen, koelkussen, rolstoel, schuim, ijs-gel stoelkussen."High Quality Comfortable En Non-slip Gel Autozitkussen Kantoorstoel Mat Pad Cool Cushion Rolstoel Foam Ice Gel Seat Cushion" (in Frisian)Hôge kwaliteit komfortabele en net-slip sûne stoel mat päd cool kussen rolstoel foam iis gel stoel kussen."Hoog Kwaliteit Comfortabele en Anti-slip Gel Auto Stoel Kantoorstoel Mat Kussen Koele Kussen Rolstoel Schuim IJs Gel Stoelkussen"

Lês mear

x

x